Advanced Auto Trends, Inc. takes pride in our complete in-house

tool room capabilities. Our dedicated staff of professionals – including fully trained technicians and

engineers with years of experience in tooling and fixture design and build – repeatedly demonstrates the ability to build complex molds or dies, engineering changes, and perform

any necessary maintenance, all with quick turn around.

Advanced Auto Trends, Inc. takes pride in our complete in-house

tool room capabilities. Our dedicated staff of professionals – including fully trained technicians and

engineers with years of experience in tooling and fixture design and build – repeatedly demonstrates the ability to build complex molds or dies, engineering changes, and perform

any necessary maintenance, all with quick turn around.

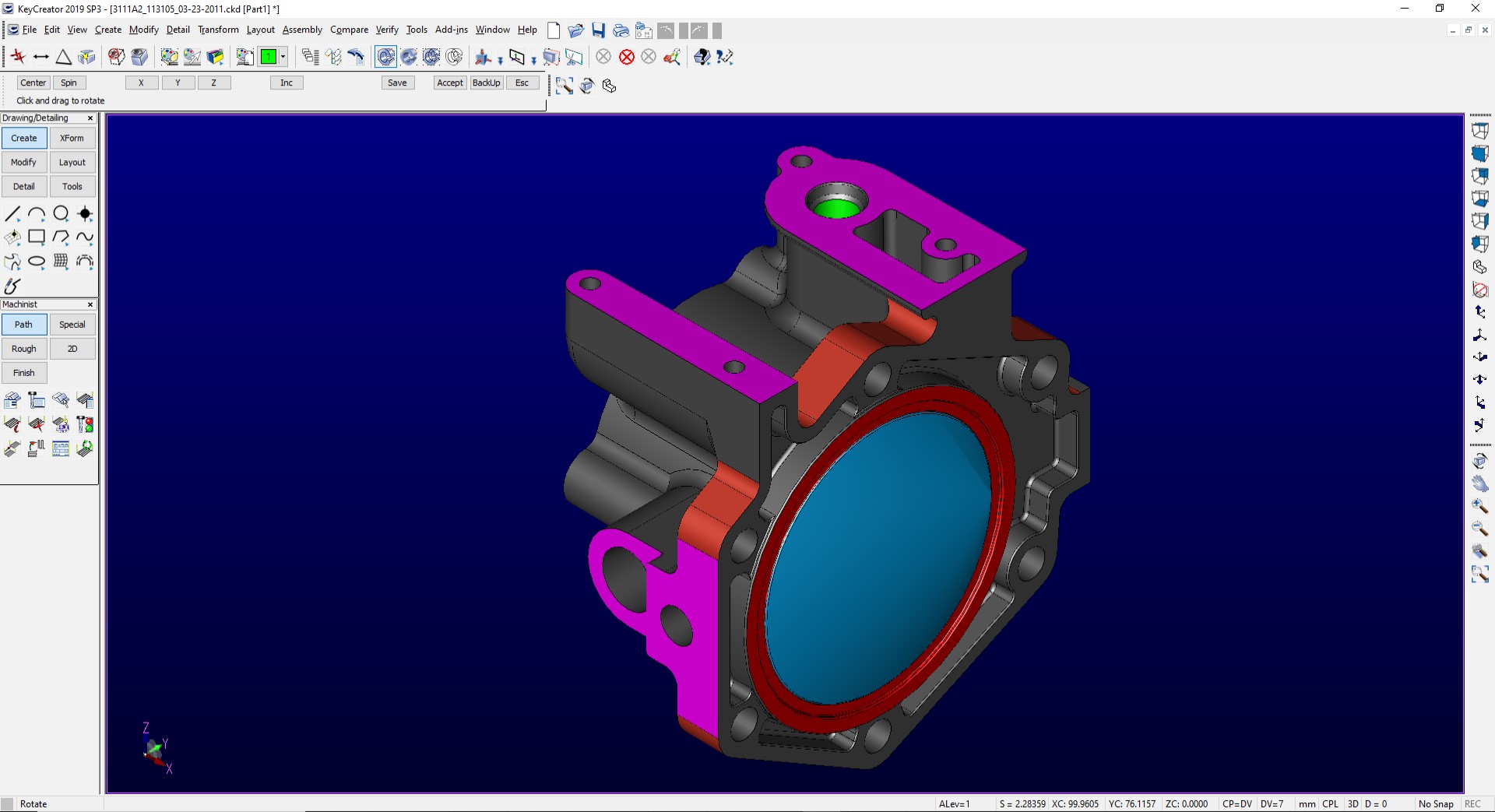

Our in-house tool room can build and maintain complex prototype and production injection molds as well as stamping dies. Our CNC machining envelope ranges up to 72” x 35” x 30” and includes vertical machining centers as well as 4 axis wire EDM capabilities. Our on-site CMM enables us to consistently validate components up to 40” x 28” x 18”.

Our tooling services include:

- Engineering changes

- Mold maintenance

- Progressive dies

- Mold builds

- Wire EDM

- Sinker EDM

- Mold repair

Our engineering department offers

superior part design, material selection, functional requirements, engineered thermoplastics, mold design,

automated assembly and error proofing operations and processing. Our expertise in the design of plastic and

progressive die parts allows us to support our customers in optimizing their designs.

Our engineering department offers

superior part design, material selection, functional requirements, engineered thermoplastics, mold design,

automated assembly and error proofing operations and processing. Our expertise in the design of plastic and

progressive die parts allows us to support our customers in optimizing their designs.