Advanced Auto Trends

Advanced Auto Trends

At Advanced Auto Trends, quality isn’t just a requirement — it’s the foundation of everything we do. From the first design discussion to final production, every team member is committed to delivering excellence. We believe that focusing on quality not only builds superior products but also strengthens our reputation, drives reliability, and earns lasting customer trust. For us, quality is more than a goal — it’s the clearest and fastest path to true success.

As a trusted leader in the injection molding industry, Advanced Auto Trends is proud to be IATF certified. This globally recognized certification reflects our commitment to quality, consistency, and continuous improvement in serving the automotive sector and beyond. Our IATF certification ensures that every product we manufacture meets the highest standards for performance and reliability, reinforcing our dedication to exceeding customer expectations and maintaining operational excellence.

At Advanced Auto Trends, we take quality seriously by utilizing in-house error-proofing equipment throughout our injection molding operations. Our internal systems are designed to identify and eliminate potential defects during production, ensuring every part meets exact specifications before it leaves our facility. By maintaining full control over the error-proofing process, we deliver superior consistency, reduce rework, and provide our customers with reliable, high-performance components.

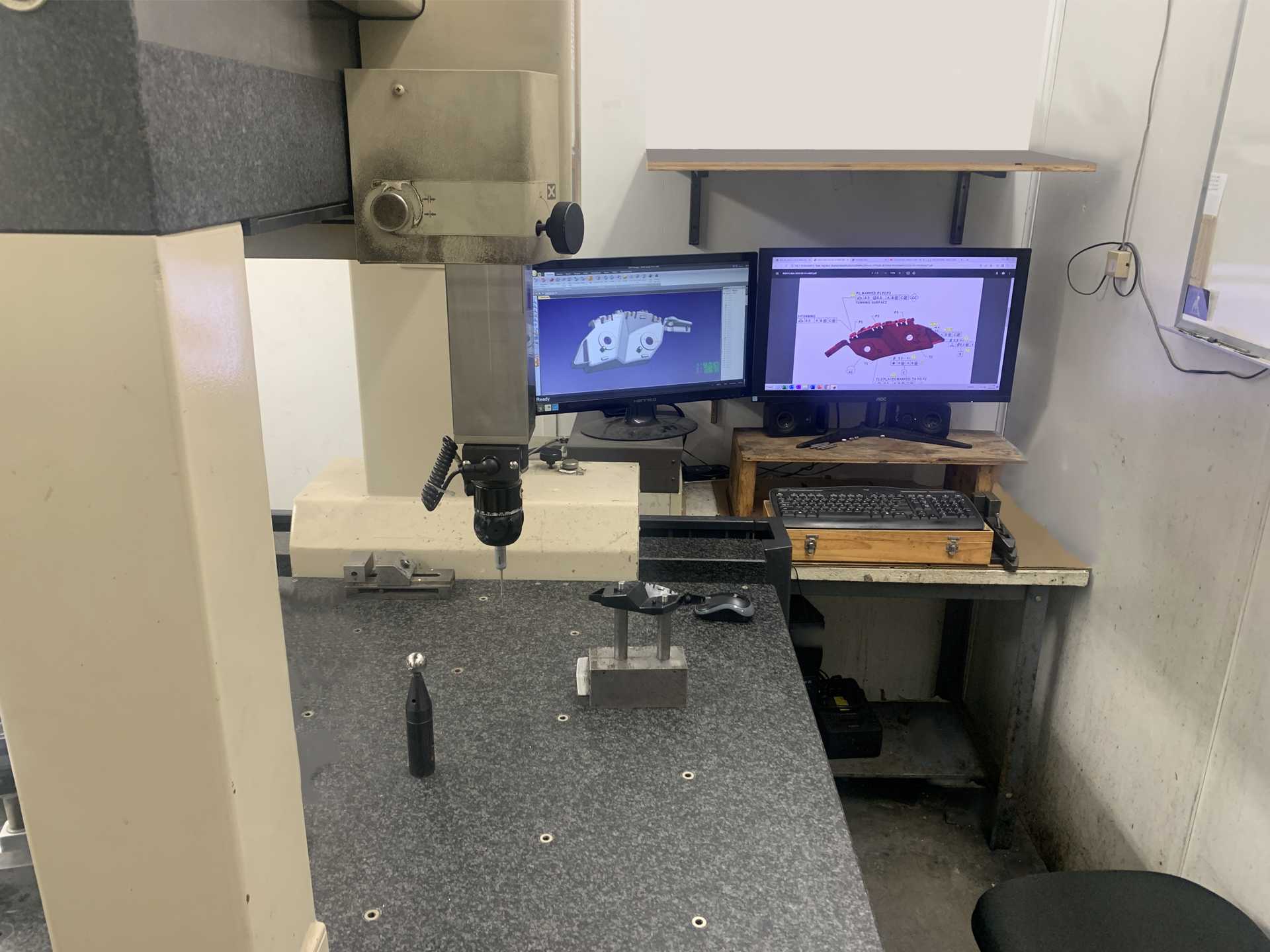

At Advanced Auto Trends, we are equipped with two on-site Coordinate Measuring Machines (CMMs) to support precise dimensional inspections and PPAP (Production Part Approval Process) requirements. Our CMM capabilities ensure that every part meets strict quality and engineering specifications, providing accurate measurement data for both production validation and continuous quality assurance. This investment in advanced metrology strengthens our commitment to delivering reliable, high-performance injection molded components.

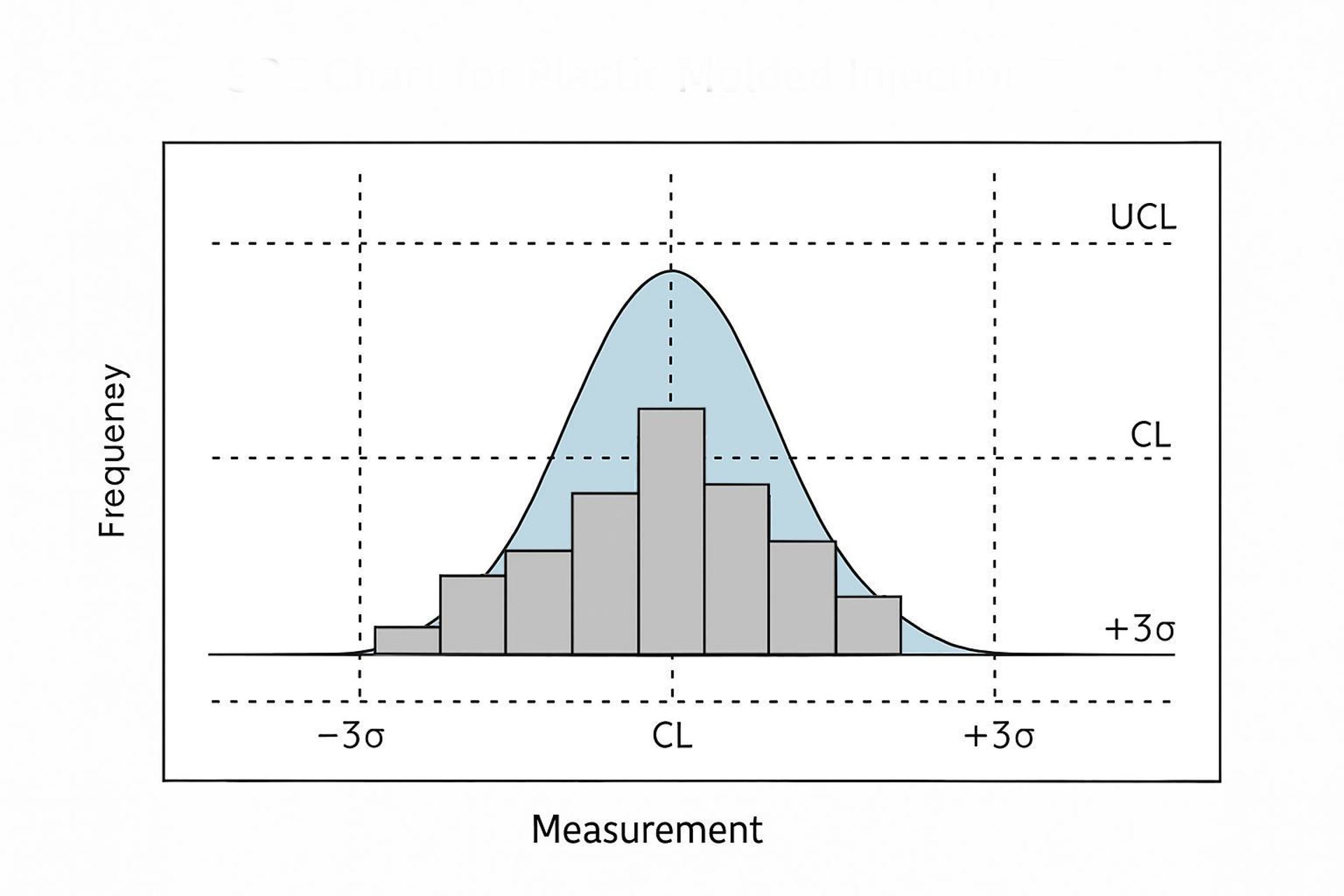

At Advanced Auto Trends, we apply disciplined use of Statistical Process Control (SPC) to closely monitor and maintain the stability of our injection molding processes. By analyzing real-time production data, we can quickly detect variations, make informed adjustments, and ensure consistent part quality. Our commitment to rigorous SPC practices helps us deliver reliable, high-precision components that meet or exceed customer expectations.

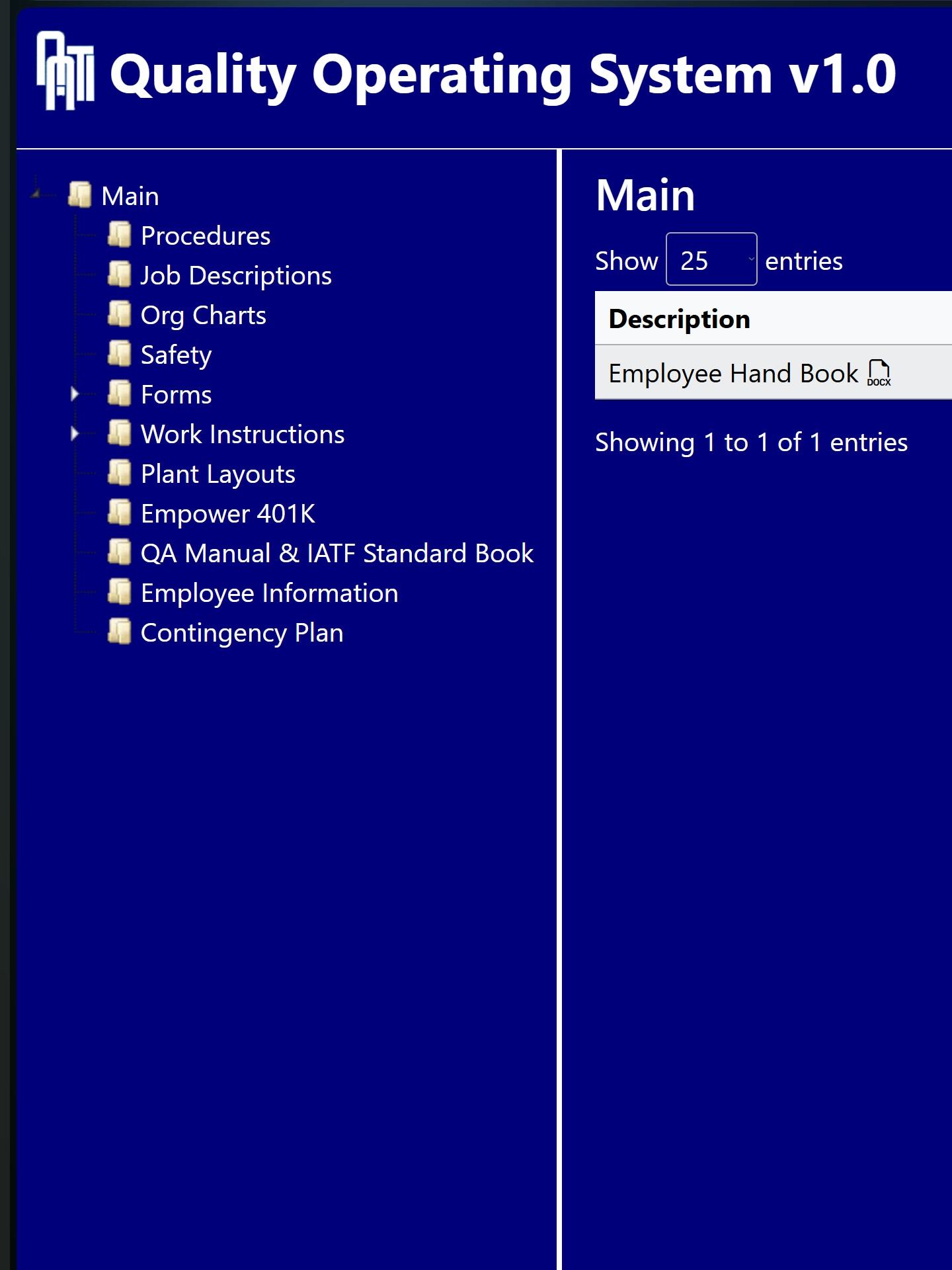

At Advanced Auto Trends, our online quality operating system provides structured procedures to manage every aspect of our business operations. This centralized platform ensures that all colleagues have immediate access to up-to-date processes, promoting clarity, consistency, and accountability across all departments. By maintaining a shared system, we strengthen communication, streamline workflows, and uphold the high-quality standards our customers rely on.

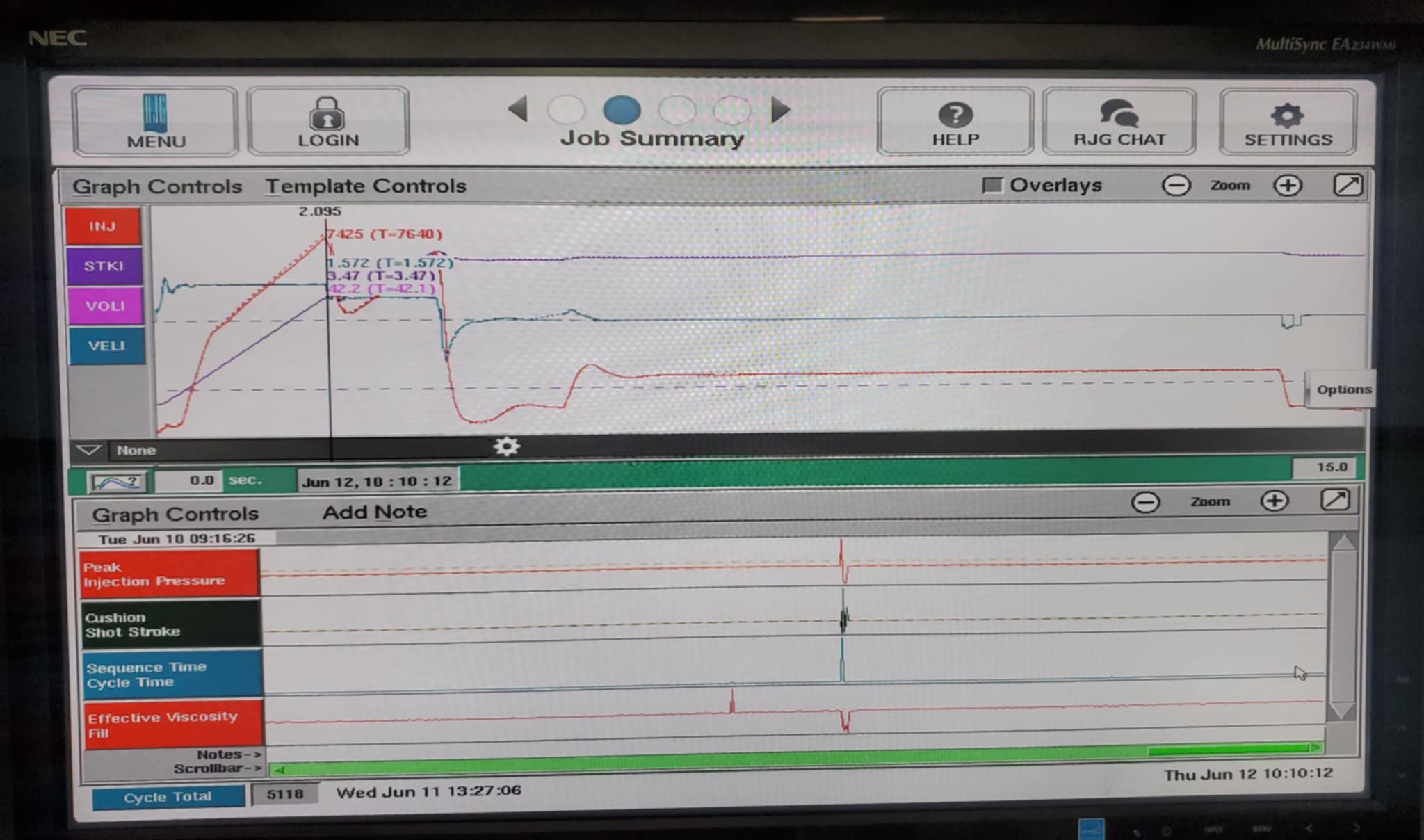

At Advanced Auto Trends, our Certified Mold Process ensures that every mold setup is developed, optimized, and closely monitored by our skilled process technicians. Through disciplined setup and oversight, we maintain consistent, high-quality production runs, minimizing variability and maximizing efficiency. This commitment to process control helps us deliver reliable, precision-molded parts that meet the exacting standards of our customers.