Advanced Auto Trends

Advanced Auto Trends

Our company offers efficient, high-precision manufacturing of in-molded inserts and components using 55 to 1100 ton injection molding presses. With robotic loading, process monitoring for tight tolerances, and integrated component molding, we reduce waste and enhance flexibility. Our experience and deep operational insights enable us to provide optimized, reliable equipment solutions for any part assembly need.

Our company specializes in auto and semi-automation molding, ideal for high-volume production. Utilizing multi-cavity tooling, we deliver low-cost, efficient solutions that maximize output while maintaining consistent quality, making it a perfect fit for large-scale manufacturing needs.

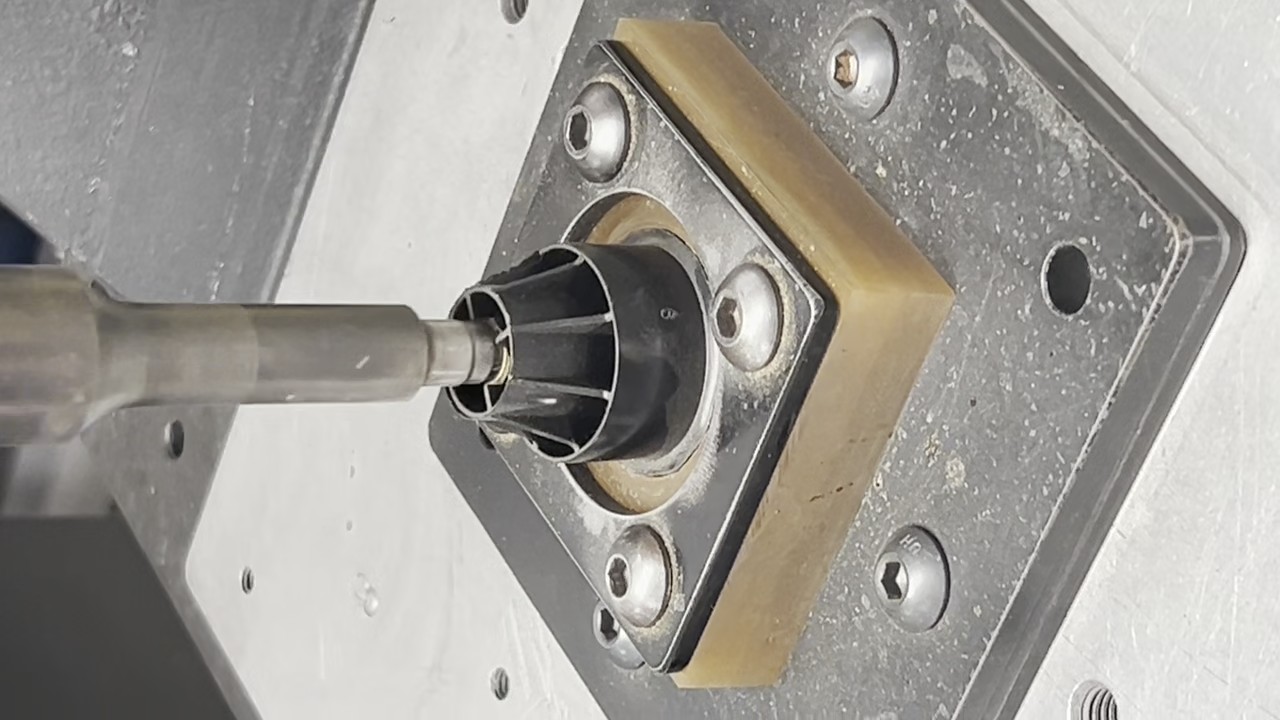

Our company offers sonic welding as a reliable, low-cost solution for bonding components together. This process streamlines production by reducing manufacturing steps while providing greater flexibility in design and assembly, making it an efficient choice for a wide range of applications.

Our company features a unique cut and sew process that allows us to sew directly through plastics, eliminating multiple manufacturing steps and improving efficiency. With precision laser-cut patterns and an in-house team of skilled sewing professionals, we deliver high-quality, customized solutions that meet exacting design and performance standards.

Our company offers in-house stamping capabilities up to 400 tons, enabling the production of high-quality parts ready for insert molding. This vertical integration gives us complete control over the components used in our molding processes, ensuring consistency, efficiency, and superior part performance from start to finish.